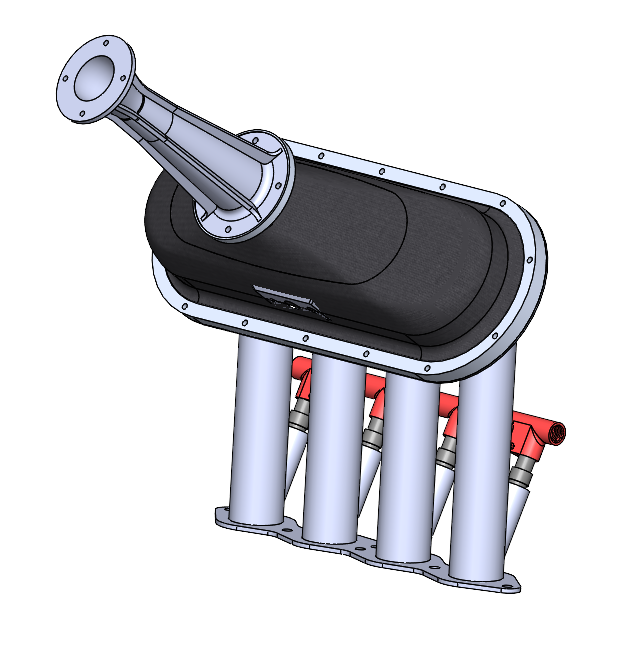

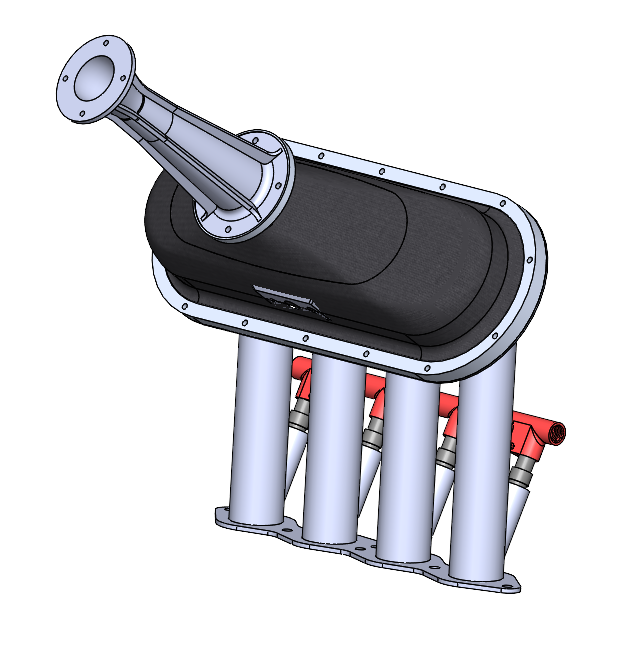

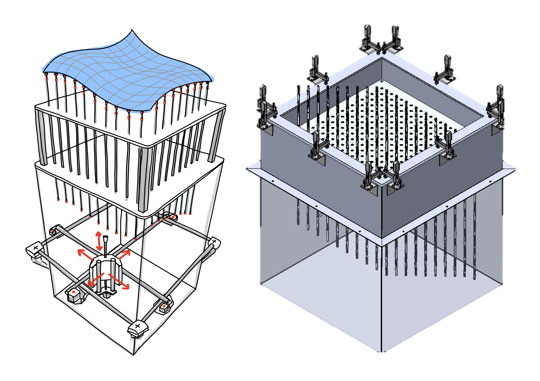

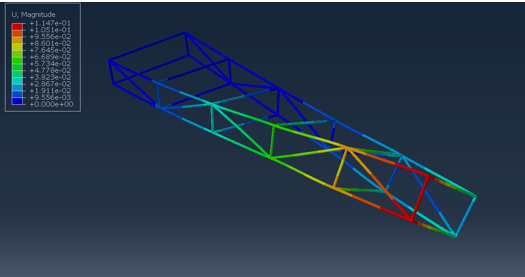

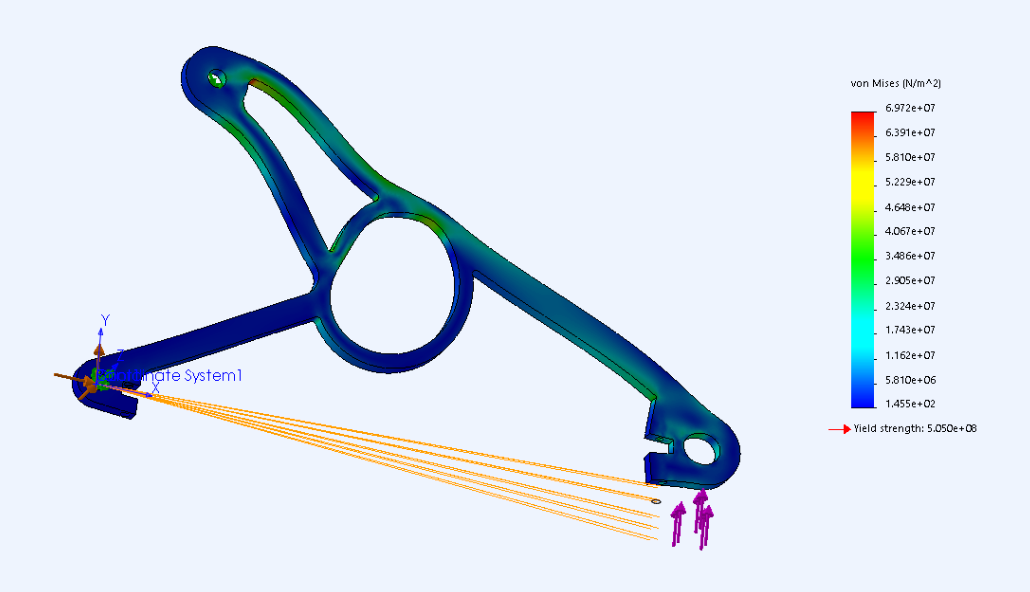

Air Intake System

Designed and optimized the carbon fibre intake system for the UBC formula style student car.

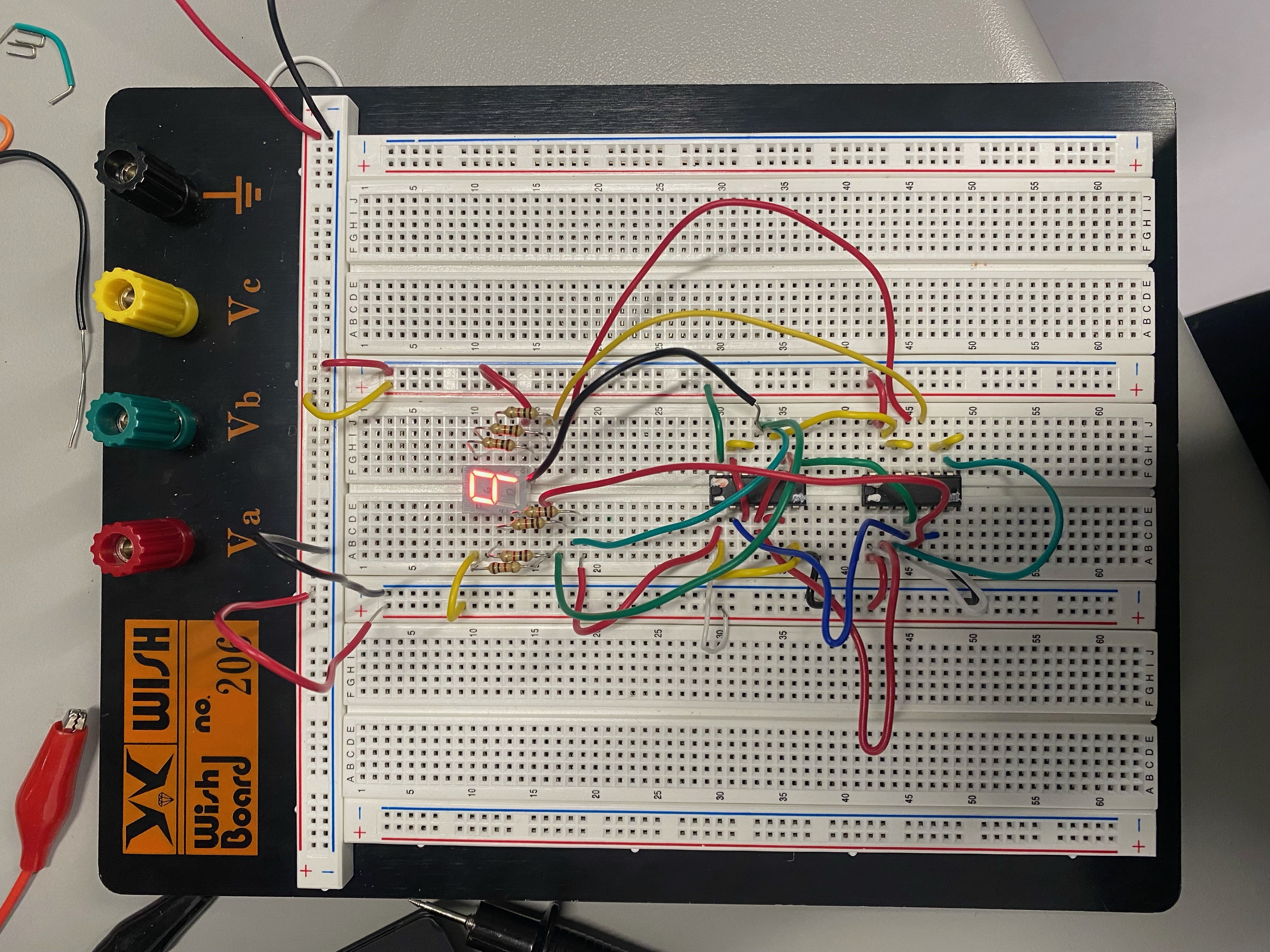

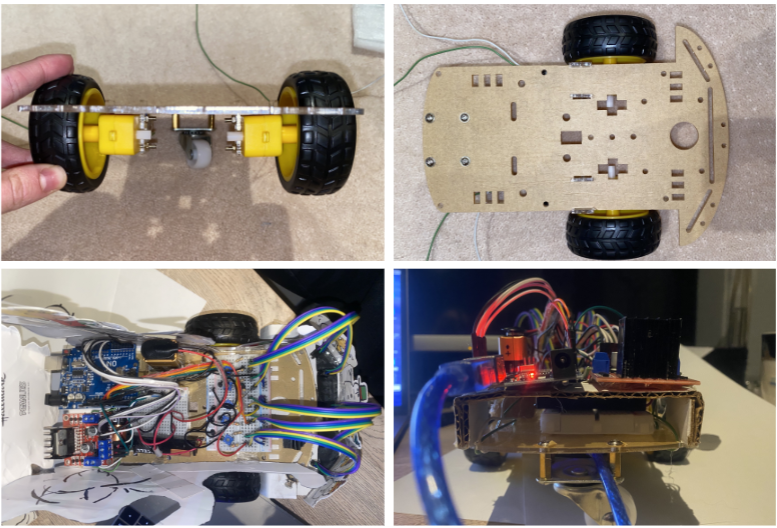

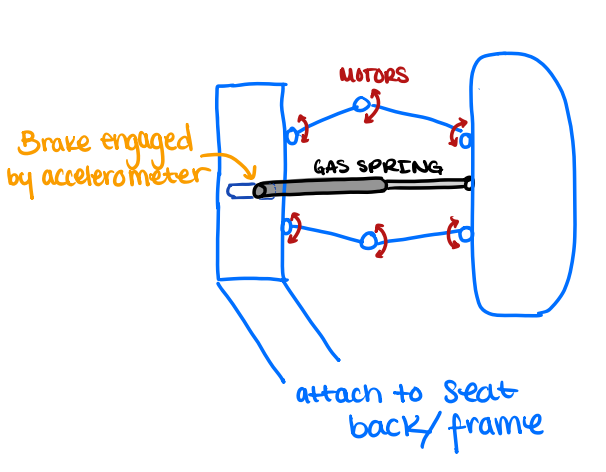

Here are a few of projects I've worked on throughout my degree. There's a mixture of mechanical, electrical, and software based projects.

My passion for engineering stems from a profound sense of optimism towards our collective future and an innate love for problem solving and becoming more efficient. I firmly believe that with every challenge we face, there lies an opportunity to innovate and redefine the boundaries of what's possible. As an integrated engineer, I embrace a multi-disciplinary approach and aim to feed all my curiosities into a wide variety of projects. I have always been drawn to the intersections of diverse ideas and interests, which come together to foster new ideas. It's at these intersections where cutting-edge innovations are discovered, transforming ideas into tangible projects that promise a brighter, more sustainable world.